January 28, 2026

Premium Natural Stone Supplier Since 1999 +90 536 999 14 09

Dragon Marble, established in 1999, is a leading Syrian-Turkish marble and natural stone exporter, serving over 80 countries worldwide. We specialize in Syrian bush-hammered stone, Turkish marble, and custom stone processing for architectural and commercial projects. Trusted by thousands, we deliver quality, precision, and international standards in every slab.

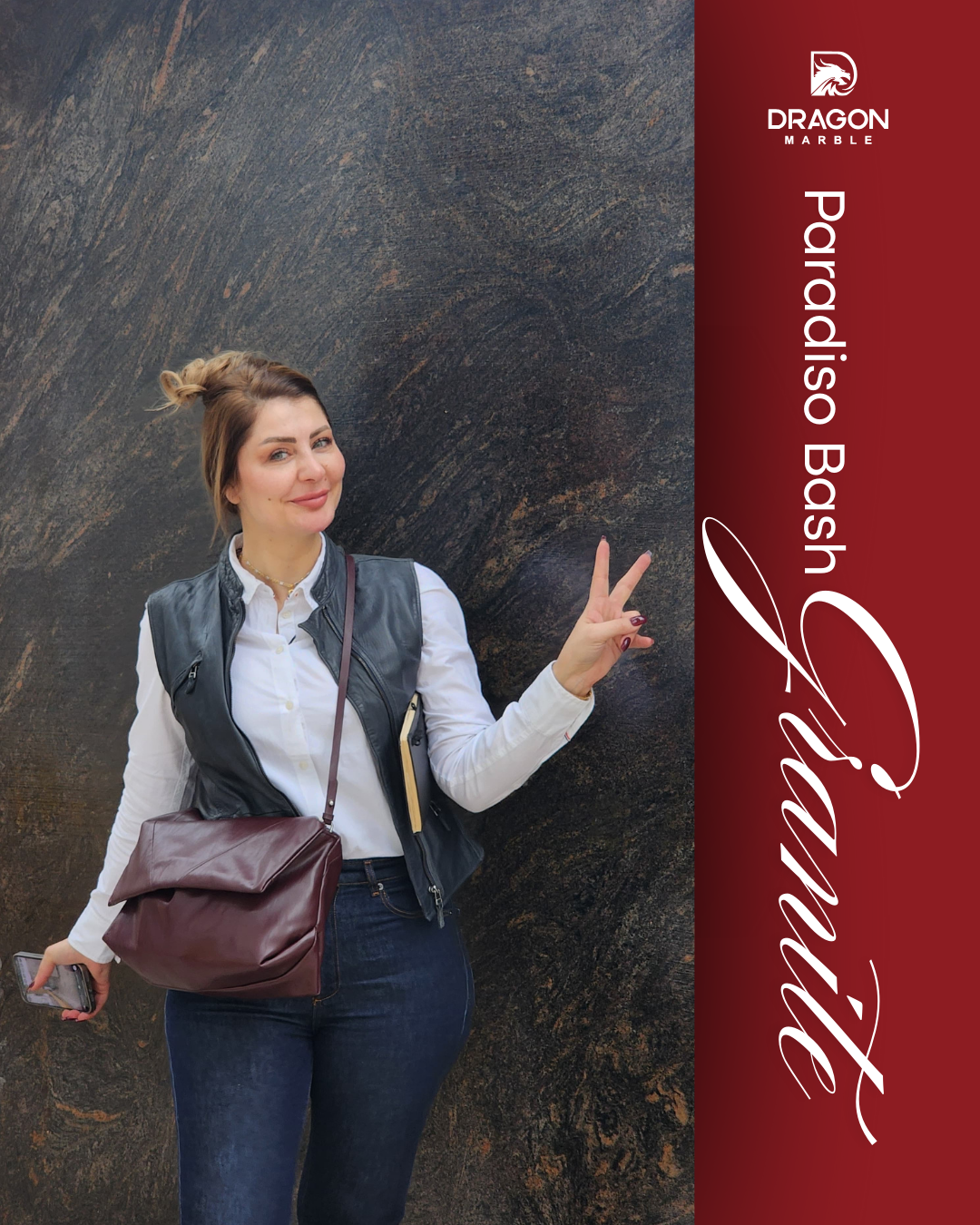

لماذا يُعد الجرانيت الهندي الخيار الأفضل للمشاريع والمطابخ؟ مميزات الجرانيت الهندي الطبيعي مميزات الجرانيت الهندي الطبيعي جرانيت طبيعي عالي الكثافة مقاوم للحرارة والرطوبة مناسب للمطابخ والأرضيات عمر افتراضي طويل مظهر فاخر يناسب المشاريع الكبرى يُعتبر الجرانيت الهندي من أكثر أنواع الجرانيت طلبًا في الأسواق بسبب جودته العالية وتنوع ألوانه، مما يجعله خيارًا مثاليًا للمقاولين وأصحاب المشاريع في سوريا. Dragon Marble | خبراء الجرانيت الهندي في الهند وجودنا المباشر في الهند في Dragon Marble نعمل مباشرة من الهند عبر شبكة موردين ومحاجر معتمدة، مما يضمن: استيراد مباشر من الهند بدون وسطاء – تحكم كامل بالجودة والمقاسات – تجهيز حمولات جرانيت جاهزة – أسعار جرانيت منافسة للجملة – – شحن بحري جرانيت إلى سوريا باب المستودع نخدم السوق السوري بتركيز خاص هذا الشهر، مع توفير حلول B2B متكاملة للمشاريع والمقاولين. أنواع الجرانيت الهندي المتوفرة لدى Dragon Marble Bash Paradiso Granite جرانيت ريفر بلاك الهندي الوصف:جرانيت أسود بخطوط طبيعية تشبه مجرى الأنهار، يعطي طابعًا تصميميًا فريدًا. الاستخدامات: – المطابخ الحديثة – الأرضيات – الواجهات الداخلية المميزات: – جرانيت طبيعي هندي – تصميم مميز – طلب مرتفع في السوق السوري – مناسب للمشاريع الخاصة River Black Granite جرانيت ريفر بلاك الهندي الوصف:جرانيت أسود بخطوط طبيعية تشبه مجرى الأنهار، يعطي طابعًا تصميميًا فريدًا. الاستخدامات: – المطابخ الحديثة – الأرضيات – الواجهات الداخلية المميزات: – جرانيت طبيعي هندي – تصميم مميز – طلب مرتفع في السوق السوري – مناسب للمشاريع الخاصة Tan Brown Granite جرانيت تان براون الهندي الوصف:جرانيت بني داكن مع بقع سوداء وحمراء، يعطي إحساسًا بالفخامة والقوة. الاستخدامات: – مطابخ – أرضيات – مشاريع سكنية وتجارية المميزات: – لون دافئ وفخم – مقاومة عالية للعوامل الخارجية – جرانيت هندي عالي الجودة – مناسب للمقاولين Black Galaxy Granite جرانيت بلاك جالاكسي (مقاسات أندرسايز) الوصف:من أشهر أنواع الجرانيت الأسود الهندي عالميًا، يتميز بلون أسود عميق ولمعان ثابت. يتميز بنقاط ذهبية لامعة، بمقاسات أندرسايز و ستندرسايز تناسب المشاريع التي تبحث عن سعر اقتصادي مع مظهر فاخر. الاستخدامات: جرانيت للمطابخ – جرانيت للأرضيات – مشاريع سكنية وتجارية – المميزات: جرانيت هندي فاخر – سعر مناسب للجملة – متوفر فورًا – مناسب للمقاولين – لماذا تختار Dragon Marble؟ مورد جرانيت معتمد خبراء الجرانيت الهندي جودة عالمية استيراد مباشر من الهند أسعار جرانيت منافسة أفضل سعر جرانيت هندي للجملة تركيز خاص على السوق السوري الشحن والتوريد إلى سوريا شحن جرانيت من الهند شحن بحري جرانيت شحن جرانيت إلى سوريا وصول الشحنات باب المستودع حمولات جرانيت جاهزة توريد جرانيت للمشاريع الكبرى إذا كنت تبحث عن جرانيت هندي فاخر للمطابخ، الأرضيات، أو المشاريع الكبرى مع شحن مباشر من الهند إلى سوريا، فإن Dragon Marble هي شريكك الموثوق. 📩 تواصل معنا الآن📦 احجز حمولة جرانيت📞 اطلب عرض سعر خاص للمشاريع والمقاولين Dragon Marble – وجهتك الأولى للجرانيت الهندي

مقدمة يُعتبر الجرانيت الأسود الهندي من أكثر أنواع الحجر الطبيعي طلبًا في الأسواق العربية، لما يجمعه من قوة، فخامة، ولمعان يدوم سنوات طويلة. ويأتي في مقدمة هذه الأنواع كل من Black Galaxy Granite وRiver Black Granite، حيث يُستخدمان بكثرة في المطابخ، الأرضيات، الواجهات، والمشاريع الكبرى. إذا كنت تبحث عن جرانيت أسود هندي فاخر بجودة عالمية وسعر منافس، فهذا الدليل سيساعدك على الاختيار الصحيح. ما هو Black Galaxy Granite؟ Black Galaxy Granite (جرانيت بلاك جالاكسي) هو نوع من الجرانيت الطبيعي الهندي يتميز بلونه الأسود العميق مع نقاط ذهبية لامعة تشبه النجوم. مميزاته: لون أسود فاخر ولمعان طبيعي. مقاوم للخدش والحرارة. مثالي لـ جرانيت أسود للمطابخ. عمر طويل وصيانة سهلة. ما هو River Black Granite؟ River Black Granite (جرانيت ريفر بلاك) يتميز بلونه الأسود المتدرج مع تموجات طبيعية ناعمة. مميزاته: مظهر هادئ وأنيق. مناسب للمطابخ والأرضيات. خيار ممتاز لـ جرانيت أسود فاخر. مقاوم للرطوبة والحرارة. استخدام الجرانيت الأسود للمطابخ يُعد الجرانيت الأسود للمطابخ من أفضل الخيارات للباحثين عن الفخامة والعملية. لماذا تختاره؟ يتحمل الحرارة العالية. سهل التنظيف. مظهر فاخر يدوم سنوات. أشهر الخيارات: جرانيت بلاك جالاكسي للمطابخ. جرانيت ريفر بلاك للمطابخ. شحن جرانيت من الهند إلى سوريا تُعد الهند من أكبر الدول المصدرة للجرانيت عالميًا، ويُعتبر استيراد جرانيت من الهند أفضل طريقة للحصول على جودة عالية وسعر مناسب. مراحل الشحن: اختيار النوع والمقاس. تجهيز الطلبية. شحن بحري جرانيت. شحن جرانيت إلى سوريا حتى باب المستودع. لماذا Dragon Marble مورد جرانيت معتمد؟ Dragon Marble هي وجهتك الأولى للجرانيت الهندي. نقاط القوة: مورد جرانيت موثوق. استيراد مباشر من الهند. أسعار جرانيت منافسة. توريد جرانيت للمشاريع. أسعار الجرانيت الهندي تعتمد الأسعار على: النوع (Black Galaxy أو River Black). السماكة والمقاس. التشطيب. الكمية. مع Dragon Marble ستحصل على: – جرانيت جودة عالية بسعر مناسب. – جرانيت للمطابخ بسعر خاص. – جرانيت جملة للمقاولين. الخلاصة إذا كنت تبحث عن جرانيت أسود هندي فاخر لمطبخك أو مشروعك، فإن Black Galaxy Granite وRiver Black Granite هما الخيار المثالي من حيث الجودة، الجمال، والسعر.

The marble and granite industry has long been a critical contributor to global construction, design, and exports. Today, governments are being urged to take a more proactive role in supporting the growth of this sector—especially in marble-rich countries like Turkey, Greece, and Italy. Strategic support for the natural stone industry can unlock economic opportunities, increase exports, and drive foreign investment. With the right policies and infrastructure, countries can significantly strengthen their global position in marble and granite exports. Turkey’s Leadership in Global Marble Exports According to the Istanbul Mineral Exporters’ Association, Turkey exported over 7.94 million tons of natural stone in 2018—including marble, granite, travertine, and slate—with a total export value of $2.05 billion USD. This achievement positions Turkey as the world’s top exporter of processed and unprocessed marble, ahead of Greece and Italy. Government-backed incentives, improved mining infrastructure, and export-friendly policies have played a key role in Turkey’s dominance in the international marble market. Marble in the Middle East: The Case of Masjid al-Haram In the Middle East, marble is not just a luxury—it’s a necessity, especially in extreme climates like Saudi Arabia. A remarkable example is the use of Thasos marble in Masjid al-Haram, the Grand Mosque in Makkah. Despite temperatures exceeding 50°C, the mosque’s floors remain cool. This is thanks to Thasos marble, a high-quality white marble imported from Greece, known for its ability to reflect sunlight and dissipate heat. According to the General Presidency for the Affairs of the Two Holy Mosques, the decision to use Thasos marble was made to ensure comfort and safety for millions of pilgrims performing Hajj and Umrah, especially during the hot summer months. Final Thoughts The marble and granite sector represents a powerful economic opportunity when supported by government initiatives and smart policies. With strategic investment, countries like Turkey continue to lead, while others benefit through intelligent import decisions—like Saudi Arabia’s use of Thasos marble for thermal comfort and performance. As demand for sustainable and climate-responsive stone solutions grows, collaboration between governments, architects, and industry leaders will define the future of the global marble market.

Marble cutting is a crucial stage in natural stone processing and determines the quality, usability, and final look of the stone. Depending on the block size, shape, and project requirements, different cutting technologies are used to optimize material yield and minimize waste. Marble Cutting Methods There are two primary methods for cutting marble: 1. Multi-Wire Cutting Used primarily for large marble blocks, multi-wire machines slice stone into slabs with precision. This method is fast, efficient, and ideal for high-volume production. 2. Block Cutters Block cutters are best suited for smaller or irregular-shaped blocks. This process produces strips of marble that are later refined into tiles, stairs, or custom shapes using miter saws or other finishing equipment. Choosing the right cutting method depends on several factors: Block dimensions and geometry Desired final product (slabs, tiles, staircases, etc.) Stone quality and texture Marble Finishing Types Once the marble is cut, it goes through a finishing process to enhance its appearance, texture, and application suitability. There are several types of finishes, each offering a distinct look and feel: 🔹 Polished Finish Delivers a glossy, mirror-like surface, ideal for luxury interiors and high-end projects. It enhances the stone’s natural color and veining. 🔹 Honed Finish Creates a smooth, matte surface by removing scratches and imperfections. Best for areas that require a subtle, elegant look without reflection. 🔹 Aged Finish Offers a rugged, naturally worn appearance, simulating the effect of time and exposure. Commonly used in restoration projects or rustic designs. 🔹 Bush-Hammered Finish Achieves a rough, textured surface with anti-slip properties, making it ideal for outdoor flooring and public spaces. 🔹 Sanded Finish Produces a lightly textured, non-glossy surface, less coarse than bush hammering, suitable for contemporary applications. 🔹 Split-Face Finish Provides a highly textured, rustic look, often used for wall cladding or decorative surfaces with a natural aesthetic. Final Stage of Marble Processing After cutting and finishing, the marble is inspected, sorted, and prepared for shipment. This final stage ensures that every piece meets quality standards and is ready for installation in construction or design projects.

Natural stone, especially marble, has played a foundational role in human civilization. From primitive tools to iconic architectural wonders, marble manufacturing has evolved over thousands of years—shaped by technological advancement, human innovation, and cultural demand. Today, we trace the journey of marble manufacturing through history, examining how ancient techniques paved the way for the sophisticated methods used in modern-day stone processing. Early Beginnings: Stone Cutting in the Stone Age Stone is one of the earliest materials used by mankind, with natural deposits of marble, granite, slate, and other stones serving both practical and decorative purposes. In the Early Stone Age, humans used the most basic technique: striking a softer stone with a harder one to shape it. This process, though primitive, laid the foundation for all future developments in stone quarrying and carving. Traditional Stone Processing: Extraction & Shaping For centuries, the marble manufacturing process followed two essential steps: Extraction – Removing large stone blocks from natural deposits. Shaping – Treating, carving, or polishing stone into usable forms for tools, monuments, or buildings. While the basic sequence remained consistent, each era—from Ancient Egypt and Rome to the Renaissance—refined these methods using local knowledge and available tools. Modern Marble Manufacturing: Advanced Technology & Machinery In today’s marble industry, technology has revolutionized every stage of the process—from quarrying to shaping to finishing. Here’s how the modern marble production process works: 1. Surface Stripping Before extraction begins, crawler tractors clear surface materials that cover the marble deposits. 2. Extraction (Quarrying) Marble is extracted using one of the following methods: Drilled blasting: Holes are drilled and filled with explosives to release the stone. Air balloon technique: Airbags are inserted into natural cracks and inflated to gently separate marble blocks from the bedrock. 3. Block Classification Each marble block is unique and is classified using the following criteria: Block size Color tones Number of streaks Presence of cracks Cleanliness or purity of the material 4. Transportation & Handling Once blocks are classified, HGV lorries (heavy goods vehicles) transport them to production centers. Upon arrival, they are unloaded into the block yard using cranes and heavy-duty machinery, ensuring safe movement due to their large size and weight. 5. Stone Cutting & CNC Processing At the factory, blocks are processed with advanced CNC stone-cutting machines that can create everything from: Flat countertops Intricate architectural pieces Tiles, stairs, and decorative elements This precise, automated cutting marks a significant leap from the hand tools of the past. Final Touch: Finishing & Polishing After cutting, marble pieces undergo various finishing treatments such as: Polishing Honing Sanding Bush-hammering Aging Split-face finishing Each technique gives marble a unique surface texture, aesthetic, and function. Conclusion From the Stone Age hammer-and-chisel techniques to today’s high-tech machinery, the process of marble manufacturing has seen a remarkable evolution. What remains constant is marble’s status as a symbol of elegance, durability, and timeless beauty. At Dragon Marble, we honor this legacy by combining traditional craftsmanship with modern innovation, offering premium marble solutions to clients across the globe.

Turkey, often referred to as the “heaven of marble”, is renowned for its rich deposits of high-quality marble varieties. From classic whites to luxurious beiges and rich reds, Turkish marble is a preferred choice for architects, designers, and builders across the world. But Turkey’s marble market is not the only one leading the industry. Globally, countries like Italy and Greece also contribute a significant share to the natural stone market with their iconic marble types. In this article, we explore the most famous Turkish marble varieties and some of the world’s best-known marble types. Top Marble Varieties in Turkey Turkey is home to numerous marble types, each with its unique color, texture, and application. Below are some of the most sought-after Turkish marble varieties: 1. Crema Nova This beige marble features subtle veins, making it ideal for both classic and modern designs. Its warm tones are perfect for flooring, countertops, and wall cladding. 2. Burdur Beige A premium marble known for its soft beige tones with light veining, commonly used in luxury interiors. 3. Diana Royal This dark beige marble with white and golden veins is widely used in high-end residential and commercial spaces. 4. Cappuccino Beige A versatile marble, characterized by its light brown and beige tones with creamy accents, perfect for kitchen countertops and bathroom vanities. 5. Empire Beige A rich beige marble with golden veins, often used for creating luxurious environments in hotel lobbies and offices. 6. Muğla White One of Turkey’s most famous white marbles, often chosen for elegant floors and furniture in contemporary and minimalist designs. 7. Emperador A brown marble with rich veining, ideal for creating high-contrast aesthetics in luxury interiors. 8. Bianco Ibiza This white marble with subtle gray veins is perfect for modern architecture and sophisticated design projects. 9. Afyon White A pure white marble, renowned for its clean, sleek look, ideal for luxurious bathroom designs and modern residential spaces. 10. Afyon Sugar A white and cream-colored marble, often used for wall cladding and countertops. 11. Usak White A lighter, more subdued white marble used in high-end projects for a sleek and polished finish. 12. Marmara White A timeless white marble, famous for its fine veins and elegant appearance, widely used in monuments, statues, and flooring. 13. Marmara Equator A variation of Marmara White, with distinctive veining, used in both classic and contemporary projects. 14. White Limestone A natural, eco-friendly stone, providing a soft, smooth texture for a variety of applications, including facades and interior surfaces. 15. Travertine This porous stone is commonly used in outdoor spaces, offering a timeless, rustic feel for patios, pools, and walkways. 16. Tundra Gray A gray marble featuring subtle veins, ideal for both modern and traditional interiors. Globally Recognized Marble Types Beyond Turkey, several countries are known for producing some of the most famous marble varieties in the world. Here’s a closer look at some of the iconic global marbles: 1. Botticino Marble (Italy) This light beige marble with subtle gray veins is a classic choice for luxury residential and commercial applications. Its elegance makes it suitable for high-end flooring and countertops. 2. Carrara Marble (Italy) Famous for its white or blue-gray color with distinctive veins, Carrara marble has been used in iconic buildings like the Pantheon in Rome. It’s often chosen for interior walls, countertops, and flooring. 3. Calacatta Marble (Italy) This premium white marble with bold, golden veins is often selected for luxury interiors like kitchen countertops and bathroom surfaces. 4. Statuarietto Marble (Italy) A highly sought-after marble known for its bright white base and striking gray veining, commonly used in luxurious flooring and wall coverings. 5. Siena Marble (Italy) A rich, warm marble with earthy tones and unique patterns, typically used in classic and rustic designs. 6. Red Marble of Verona (Italy) Known for its deep red color with white veins, the Red Marble of Verona is used for creating bold, artistic designs in both interior and exterior applications. Conclusion: The Global Marble Market The marble industry continues to thrive globally, with Turkey leading the charge in producing a diverse array of marbles for different applications. Whether you are looking for the elegance of Carrara, the luxury of Diana Royal, or the warmth of Afyon Sugar, marble from both Turkey and other marble-rich regions provides an excellent option for any project. At Dragon Marble, we offer premium Turkish marble and a variety of globally sourced stones, providing top-quality solutions for both residential and commercial projects. Whether you’re planning a modern design or a classic renovation, we have the perfect marble for you.

Marble is one of the most iconic and enduring building materials in human history. Revered for its natural beauty, durability, and timeless elegance, marble has been used by civilizations around the world for thousands of years. From the pyramids of Egypt to the temples of Greece and modern luxury architecture, marble continues to hold a prestigious place in construction and design. What Is Marble and Why Is It So Special? Marble is a metamorphic rock formed when limestone is subjected to intense heat and pressure over time. This transformation results in a dense, durable stone with a smooth texture, unique veining, and a wide variety of colors and patterns—from pure white to deep black, with shades of grey, gold, green, and red in between. Its ageless aesthetic, combined with strength and workability, makes marble a top choice for architectural, decorative, and artistic uses. Ancient Use of Limestone in the Pyramids of Giza Before the widespread use of marble, limestone, its precursor, played a crucial role in ancient construction—most famously in the Pyramids of Giza. Egyptian builders used: Rough limestone for the inner core Finer white limestone for the outer casing and interior walls These materials were sourced locally in vast quantities and cut into blocks using primitive tools such as granite chisels, hammers, and pickaxes. The builders relied on manpower and simple machines like levers, pulleys, and wooden beams to extract and move the stones. The Rise of Marble in Ancient Greece and Rome Marble gained immense popularity in Ancient Greece and Rome, where it became a symbol of beauty, power, and architectural excellence. The Greeks used white marble extensively for temples, statues, and public buildings, drawn to its aesthetic purity and reflective surface. The Romans advanced marble use with larger-scale construction, importing marble from across the empire and incorporating it into columns, amphitheaters, and palaces. Despite the lack of modern equipment, ancient builders managed to quarry, shape, and transport massive marble blocks using rudimentary tools, manual labor, and ingenuity. Marble in Modern Times: A Legacy That Endures Today, marble remains a highly sought-after material for: Luxury interiors (kitchens, bathrooms, flooring) Monuments and sculptures Wall cladding and facades Hotel lobbies and commercial spaces Advanced CNC technology, diamond wire saws, and polishing machines have transformed how marble is cut and finished—yet the stone’s natural origin and historic charm still captivate designers, architects, and homeowners around the world. A Gift from Nature What makes marble truly special is that no two pieces are exactly alike. Mother Nature crafts each slab uniquely, giving marble its distinctive beauty. From Thassos White to Calacatta Gold and Afyon Sugar, every variety offers its own story, tone, and pattern—making marble both a natural wonder and a creative tool. Final Thoughts From prehistoric tools to cutting-edge architectural marvels, marble has remained a cornerstone of human creativity and construction. Its combination of strength, natural elegance, and historic significance ensures it will continue to inspire for generations to come. At Dragon Marble, we honor this legacy by offering premium natural stone solutions—sourced responsibly, processed with precision, and delivered globally.

Dragon Marble has been a trusted name in natural stone since 1999. Based in Turkey with Syrian roots, we export premium marble and stone products to over 80 countries. Quality. Tradition. Global reach.

© 2025 Created with Dragon Marble